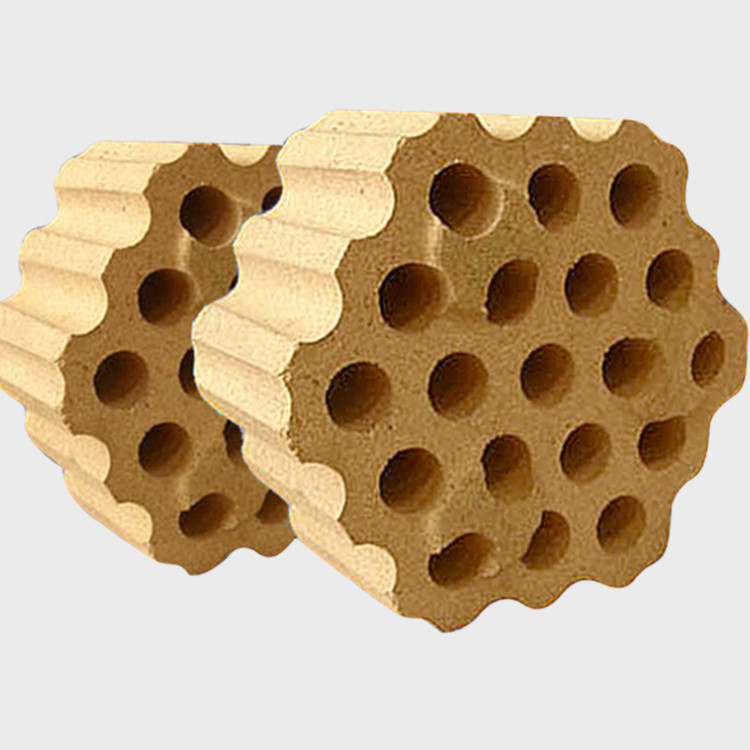

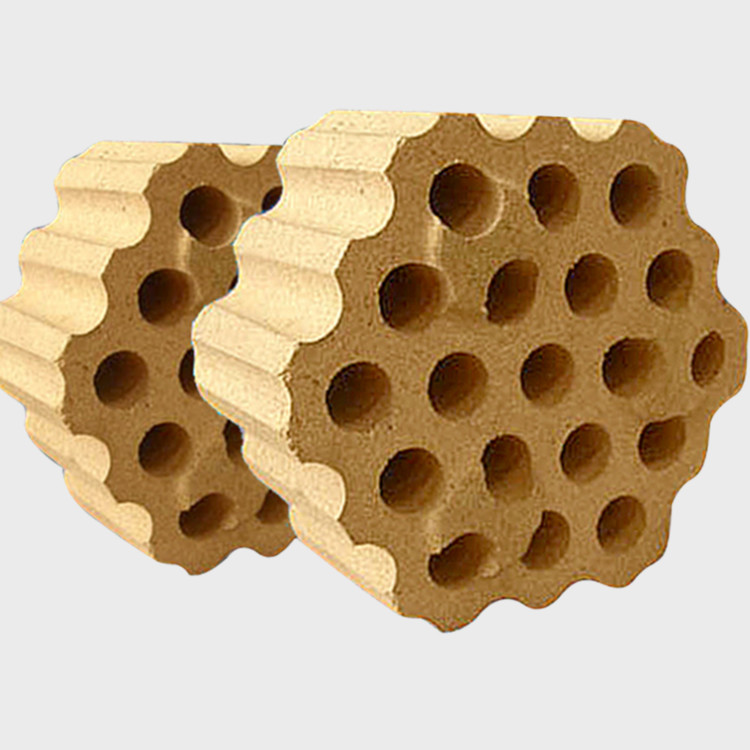

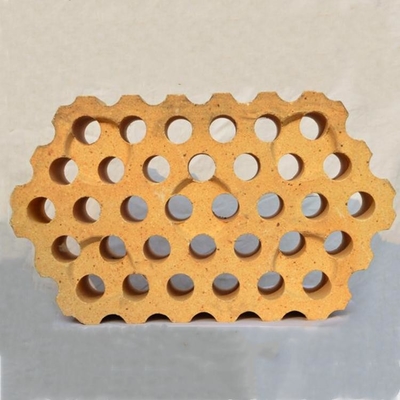

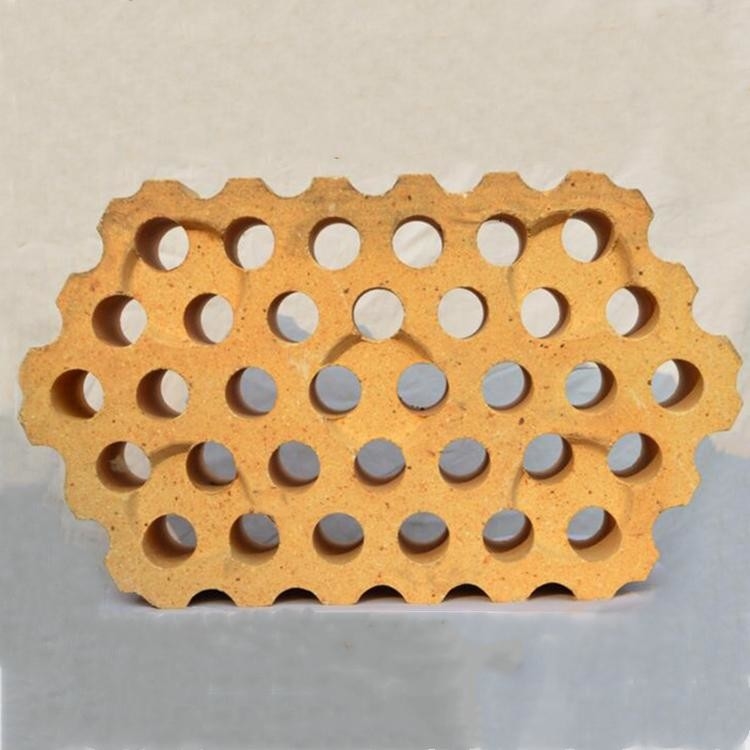

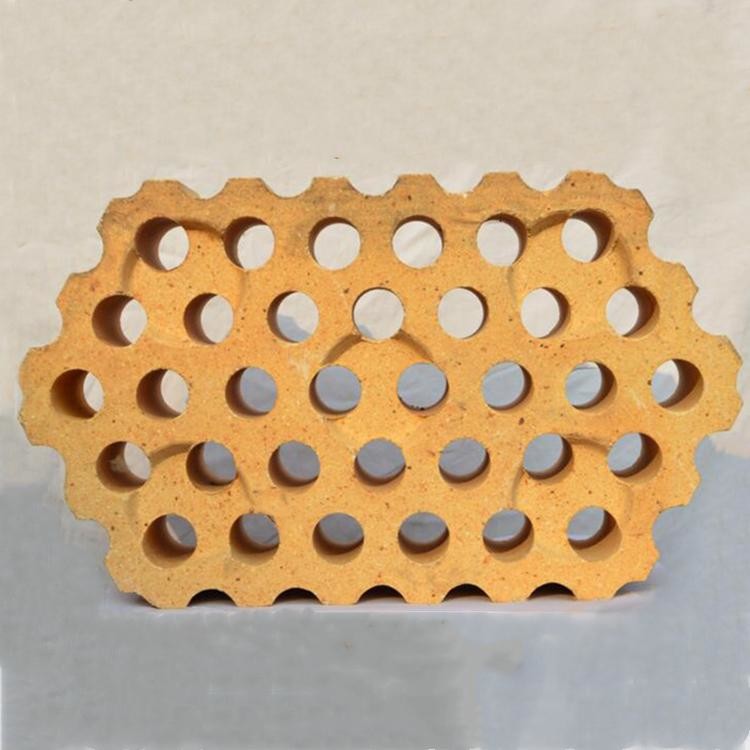

Special Shapes Fire Clay Bricks Refractory Clay Brick High Density Customized Brick

Fire clay brick is 50% soft clay and 50% hard clay clinker, according to a certain size requirements for ingredients, the molding, drying, in 1300~1400℃ high temperature firing.

Performance:

It is mainly used for carbon furnace, baking furnace, heating boiler, glass furnace, cement kiln, fertilizer classification furnace, blast furnace, the hot blast stove, coking furnace, furnace, casting and casting steel brick, etc.

Physical and Chemical Index:

|

Item/Grade

|

Fire Clay Brick |

| |

SK-30 |

SK-32 |

SK-34 |

SK-35 |

| AL2O3% (≥) |

30 |

35 |

38 |

45 |

| Fe2O3% (≤) |

2.5 |

2.5 |

2 |

2 |

| Refractoriness (SK) |

30 |

32 |

34 |

35 |

|

Refractoriness under load,

0.2MPa, °C (≥)

|

1250 |

1300 |

1360 |

1420 |

| Apparent porosity (%) |

22-26 |

20-24 |

20-22 |

18-20 |

| Bulk density (g/cm³) |

1.9-2.0 |

1.95-2.1 |

2.1-2.2 |

2.15-2.22 |

| Cold crushing strength ,MPa (≥) |

20 |

25 |

30 |

40 |

Project cases:

Project cases:

Applications:

It is mainly used in blast furnace, hot blast stove, baking furnace, carbon calciner, coking furnace, teeming ladle, casting system, boiler, cement kiln, glass furnace and all kinds of kiln linings and thermal equipment. It is applied in metallurgy, machinery, construction, casting, ceramics, electricity, petroleum, chemical industry, etc.

Related products:

Welcome you to our factory:

When you visit our factory, we will pick up you at air port.

Packing:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!